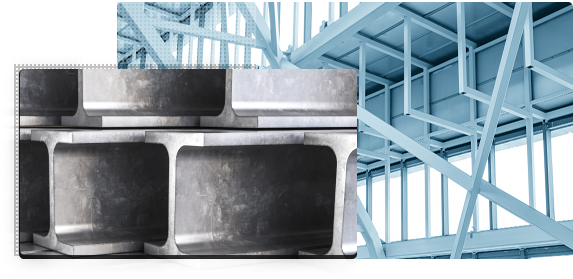

metal structures

Councils

Steel structures are the backbone of the main frame of modern industrial and commercial facilities, and are characterized by high load-bearing strength and rigidity, while maintaining their light weight compared to traditional concrete structures.

These structures include columns, airports, warehouses, dams, factories, power plants, bridges, and girders, in addition to secondary elements such as metal panels used in walls and ceilings, which are suitable for modern industrial projects.

Types of metal structures

Metal structures for factories come in a variety of smart designs to meet the needs of

every industrial project, including simple frames and advanced truss systems.

steel frame structures

Which is more common in large factories, as it provides wide open spaces without internal columns that hinder the movement of equipment or production.

prefabricated metal structures

Ideal for medium-sized projects, they are quickly manufactured and installed on-site, significantly reducing time and cost.

Composite metal structures

It combines steel and concrete to create a structural system that combines high strength with flexibility in design and use.

arched metal structures

We rely on them in warehouses or factories that require large storage spaces, and they are characterised by their streamlined shape and ability to bear loads.

Characteristics and advantages of metal structures

Steel structures boast unique properties that combine strength, flexibility, and rapid construction, making them ideal for various modern industrial sectors.

- Designed to efficiently withstand heavy loads and harsh operating conditions.

- Lighter than concrete structures, reducing foundation burdens and costs.

- Allows the creation of spacious, unobstructed interior spaces, with the ability to manipulate heights as needed.

- Elements are pre-fabricated and quickly installed on-site, significantly reducing implementation time.

- The facility can be easily expanded or modified later without disrupting operations.

- It becomes excellently resistant to high temperatures, when treated with special materials.

- Environmentally friendly thanks to the recyclable materials it is made of.

Stages of design and implementation of metal structures

The project plan includes preparing a clear timeline and financial plan that covers all implementation phases from start to finish. The required resources, such as materials, equipment, and labor, are identified, taking into account accurate scheduling of the various phases.

At this stage, the required metal materials are supplied from reliable sources, ensuring that they conform to the required specifications in terms of quality and standards. These materials include various parts such as columns, beams, and metal panels that are manufactured according to engineering drawings. The materials are transported to the work site according to the specified schedule to avoid delays in implementation.

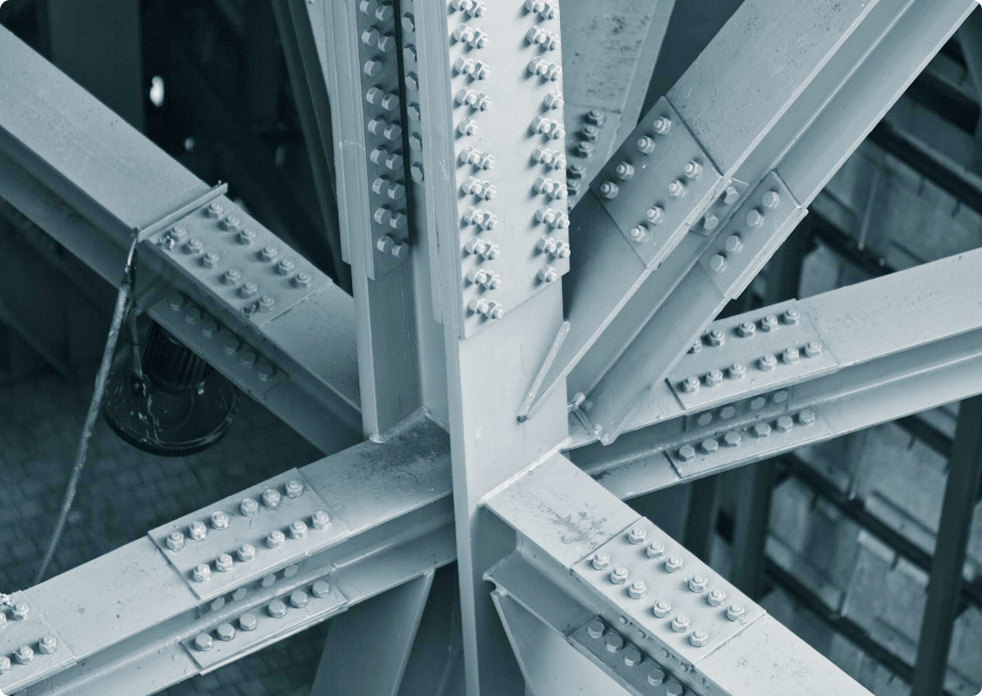

Steel structure installation involves transporting parts to the site and assembling them according to engineering drawings. Specialized equipment such as cranes is used to lift and install the metal parts accurately and safely.

During the finishing stage, we ensure that all metal parts are properly assembled and are robust. This stage also includes surface treatment against corrosion using paint or heat treatment. The structure is carefully inspected to ensure it meets all engineering standards and ensures long-term durability.

Considerations for the safety of metal structures

Despite the engineering advantages offered by steel structures, they are not without challenges that require thoughtful solutions to ensure their long-term efficiency. Therefore, at Buruj Urban Development Contracting, we take all safety considerations into account, from design to implementation.

- Determine the plant's needs in terms of space, type of operations, and expected loads for a suitable and efficient design.

- Structural engineers create designs using advanced CAD software to ensure accuracy and construction efficiency.

- Suitable steel and metal types are determined based on the load-bearing requirements and operating environment.

- Precision production of structural components in specialized factories according to approved drawings.

- The parts are transported to the project site and assembled using techniques such as welding or riveting to form the final structure.

- Application of rust-resistant paint or galvanization to ensure long-lasting durability in various environmental conditions.

- Conduct quality and safety tests to ensure the strength and durability of the structure before the facility is put into operation.